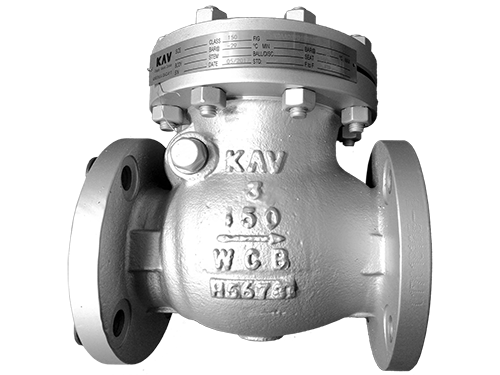

CHECK VALVES

Check valves are automatically actuated. They are opened and sustained in the open position by the force of velocity pressure and closed by the force of gravity.

Seating load and resultant tightness are dependent upon backpressure. The disc and associated moving parts may be in a constant state of movement if the velocity pressure is not sufficient to hold the valve in a wide-open and stable position.

Premature wear and noisy operation or vibration of the moving parts can be avoided by selecting the size of the check valve on the basis of flow conditions.

Check valves are used to prevent reversal of flow in horizontal or vertical pipelines.

In vertical lines, or for any angle from horizontal to vertical, they can be used for upward flow only.

KEY CHECK VALVE FEATURES

- Full /Reduced port design.

- RF, RTJ, BW, or wafer end connections.

- Anti-rotation disc.

- Horizontal or vertical service.

- Renewable or Integral seat rings available

- Non-standard valves designed according to customer specifications.

QUALITY MADE CHECK VALVES

Type:

Swing Type | Piston Type | Dual Plate Wafer | Non Slam | Titling Disc | Cryogenic

Construction:

Bolted Bonnet | Pressure seal | Wafer

CHECK VALVE SIZE & PRODUCT RATINGS

Size: | Rating: |

|---|---|

1/2" to 56" | 150lb |

1/2" to 48" | 300lb |

1/2" to 42" | 600lb |

1/2" to 36" | 900lb |

1/2" to 30" | 1500lb |

1/2" to 20" | 2500lb |